- Out of stock

The GENIE 123 separator is equipped with a membrane to separate liquids from the gas flow and is designed for applications with larger gas flows.

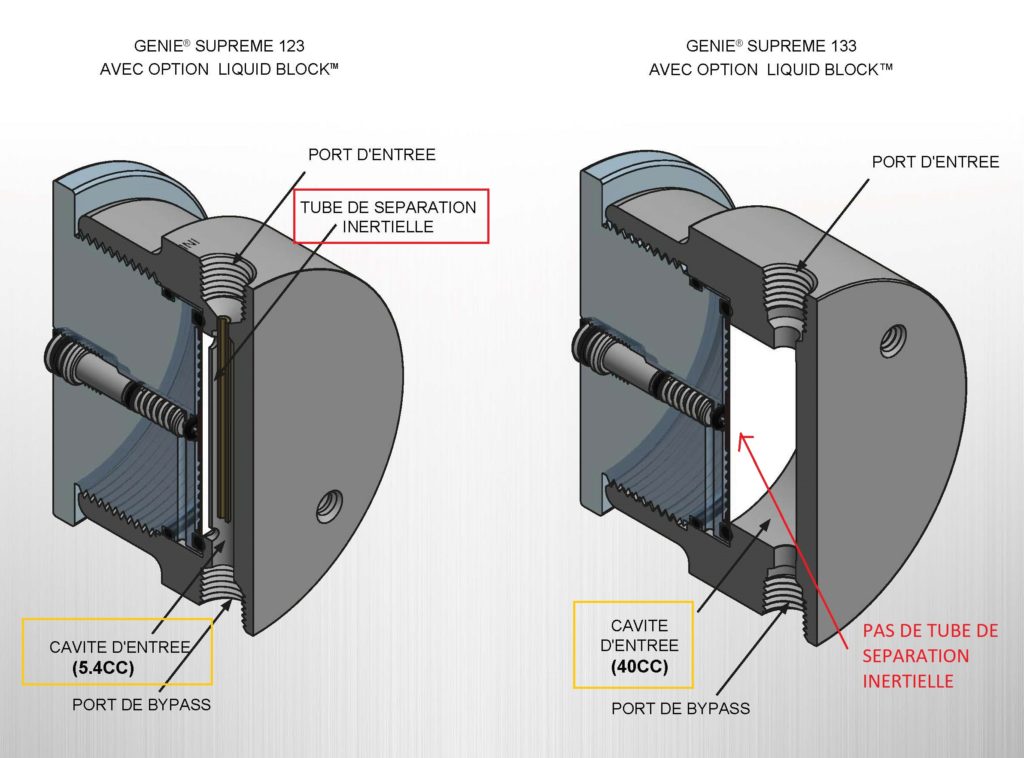

The 2 GENIE 123 and GENIE 133 separators are the largest in the A+ Corporation liquid/gas separator range. Although they can handle identical flow rates and temperatures, their design and use are different.

The GENIE 133 separator has a larger internal cavity than the GENIE 123 separator, and can withstand higher pressures.

The GENIE 133 separator is ideal for continuous sampling of a gaseous source where large quantities of liquids are present, e.g. for the collection and processing of natural gas, for CEMS and certain refinery and petrochemical gases.

It can be mounted on a sampling probe (GENIE GPHV or 760) when the probe, fitted with a membrane at its end, is invaded by liquids. It can also be mounted before an analyzer or pump to protect them.

Finally, it is recommended for sample pre-conditioning in applications where there is no bypass and liquids must be discharged from the separator by gravity.

Aware that every company, however small, has an impact on the environment, SOCLEMA is committed to sustainable development.

Find out more